In the world of craftsmanship, precision is the hallmark of excellence. Whether you’re an artisan shaping a delicate piece of jewelry, an engineer assembling intricate machinery, or a hobbyist crafting a wooden masterpiece, the pursuit of perfection is a journey filled with challenges and triumphs. Enter the realm of pressure-controlled arms—an innovation that promises to revolutionize how we approach precision tasks, offering unparalleled control and accuracy. These cutting-edge tools are not just an upgrade; they represent a seismic shift in how projects are executed, ensuring flawless results every time. With the ability to apply just the right amount of pressure, they are transforming industries and redefining what’s possible. 🌟

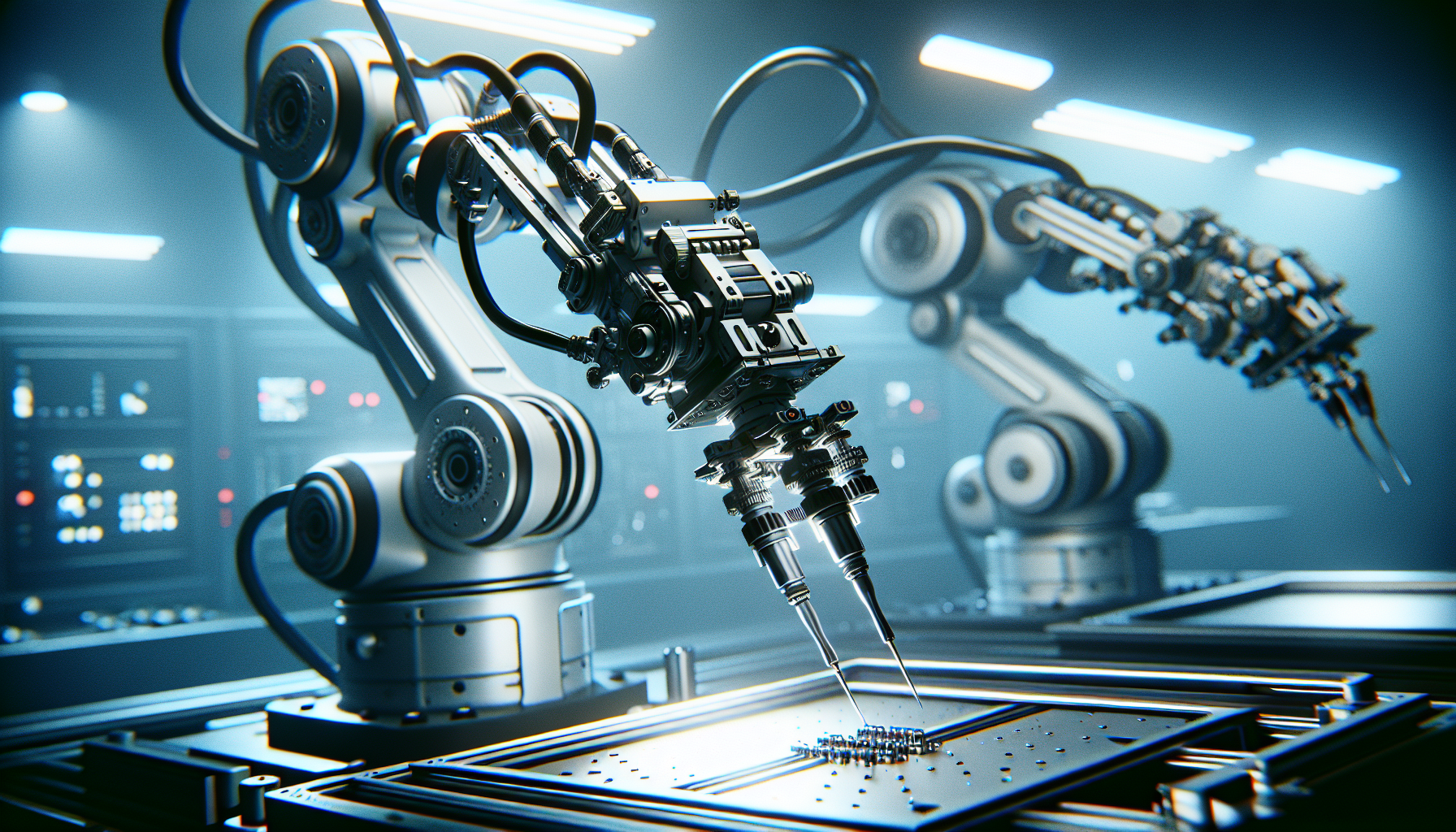

Imagine a tool so refined that it feels like an extension of your own hand, responding intuitively to the subtlest of commands. This is the magic of pressure-controlled arms. They are engineered to empower both seasoned professionals and enthusiastic amateurs, bridging the gap between human dexterity and machine precision. By integrating advanced technology with ergonomic design, these arms offer a seamless experience that enhances both efficiency and creativity. As we delve into the myriad possibilities unlocked by this innovation, we will explore how it is reshaping various fields, from manufacturing and construction to art and medicine. The potential applications are as diverse as they are exciting, promising to elevate the quality and consistency of work across disciplines.

Throughout this comprehensive exploration, we’ll dive into the mechanics and benefits of pressure-controlled arms. We’ll discuss how these tools utilize sensors and feedback systems to deliver precise force, ensuring that each movement is deliberate and exact. By maintaining consistent pressure, these arms prevent errors and reduce material waste, leading to cost savings and improved outcomes. We’ll also examine real-world case studies where pressure-controlled technology has already made a significant impact, highlighting success stories and lessons learned. From enhancing the delicate work of watchmakers to increasing the efficiency of assembly lines, the applications are truly limitless. We’ll provide insights into the latest advancements in this technology, as well as future trends that promise to further enhance its capabilities.

Finally, we’ll address the broader implications of adopting pressure-controlled arms across various sectors. What does this mean for the workforce? How will these tools influence job roles and skill requirements? And, perhaps most importantly, how can individuals and businesses prepare for this shift? By understanding the transformative power of these tools, stakeholders can position themselves at the forefront of innovation, harnessing the potential of pressure-controlled arms to achieve new heights of precision and excellence. Join us as we embark on this journey into the future of precision craftsmanship, where technology meets artistry, and where the perfect blend of human ingenuity and machine intelligence paves the way for extraordinary achievements. 🛠️✨

Understanding Pressure-Controlled Arms: A Revolution in Precision

Pressure-controlled arms represent a remarkable advancement in technology, providing unparalleled precision in a variety of fields. These tools have become indispensable in industries ranging from manufacturing to healthcare, offering a level of accuracy that was previously unattainable. In this section, we’ll delve into the fundamentals of pressure-controlled arms and explore how they are transforming numerous sectors.

The core function of pressure-controlled arms is to provide controlled movement and force, which is crucial for tasks that require high precision. Unlike traditional robotic arms, which rely on mechanical or electrical controls, pressure-controlled arms use hydraulic or pneumatic systems to fine-tune their movements. This allows them to achieve a degree of control and accuracy that is essential in delicate operations such as assembling microelectronics or conducting surgical procedures. The precision offered by these arms minimizes errors and enhances efficiency, leading to better quality outcomes.

The technology behind pressure-controlled arms is based on fluid dynamics. By manipulating the pressure of the fluid within the arm, operators can control the arm’s movement with incredible precision. This method is highly effective in environments where slight variations in force can have significant consequences. For example, in the automotive industry, pressure-controlled arms are used to apply coatings with uniform thickness, ensuring a perfect finish. Similarly, in the field of aerospace, these arms are employed to handle delicate components that require careful assembly.

Pressure-controlled arms are not only about precision; they also offer versatility. They can be programmed to perform a wide range of tasks, making them suitable for various applications. Whether it’s welding, painting, or assembling small parts, these arms can be adapted to meet the specific needs of different projects. This flexibility is a key advantage, allowing businesses to streamline their operations and reduce costs by using a single tool for multiple purposes.

Applications of Pressure-Controlled Arms in Different Industries

The versatility of pressure-controlled arms is evident in their widespread use across different industries. In manufacturing, these arms are essential for tasks that require consistent precision, such as welding and material handling. By providing uniform pressure, they ensure that welds are strong and materials are transported without damage, increasing the overall efficiency of the production line.

In the healthcare sector, pressure-controlled arms are revolutionizing surgical procedures. They provide surgeons with the ability to perform complex operations with greater accuracy, reducing the risk of human error. This is particularly important in minimally invasive surgeries, where precision is critical. These arms also assist in rehabilitation therapies by applying controlled pressure to specific areas, aiding in the recovery process.

The construction industry also benefits from the use of pressure-controlled arms. They are used to apply paints and coatings evenly, ensuring a flawless finish. Additionally, their ability to handle heavy materials with precision makes them invaluable in tasks such as installing glass panels and other delicate construction elements. The efficiency and accuracy of these arms lead to faster project completion times and reduced labor costs.

Pressure-Controlled Arms vs. Traditional Robotic Arms

To better understand the advantages of pressure-controlled arms, it’s helpful to compare them with traditional robotic arms. Below is a comparative table highlighting the key differences between the two:

| Aspect | Pressure-Controlled Arms | Traditional Robotic Arms |

|---|---|---|

| Control Mechanism | Hydraulic/Pneumatic | Mechanical/Electrical |

| Precision | High | Moderate |

| Versatility | Highly Adaptable | Limited |

| Cost | Higher Initial Investment | Lower Initial Investment |

While pressure-controlled arms require a higher initial investment, their ability to deliver consistent precision and adapt to various tasks often justifies the cost. For businesses that prioritize quality and efficiency, the benefits of pressure-controlled arms outweigh their expenses. Traditional robotic arms, on the other hand, may be suitable for simpler tasks that do not require high precision.

Technological Innovations Enhancing Pressure-Controlled Arms

The development of pressure-controlled arms has been significantly enhanced by technological innovations. Advances in sensors, artificial intelligence, and machine learning have made these arms more intelligent and responsive, allowing them to perform tasks with even greater precision and efficiency. In this section, we will explore how these technologies are integrated into pressure-controlled arms and the benefits they offer.

Sensors play a crucial role in the functionality of pressure-controlled arms. They provide real-time feedback on the arm’s position, force, and speed, enabling precise control over its movements. Modern pressure-controlled arms are equipped with a variety of sensors, including force sensors, position sensors, and pressure sensors. These sensors work together to ensure that the arm operates with the highest level of accuracy. For example, force sensors allow the arm to apply the exact amount of pressure needed for a specific task, preventing damage to delicate components.

Artificial intelligence and machine learning are also integral to the operation of pressure-controlled arms. By analyzing data from sensors, AI algorithms can optimize the arm’s performance and adapt to changes in the environment. This capability is particularly beneficial in dynamic settings where conditions may vary. Machine learning enables the arm to learn from past experiences, improving its performance over time. For instance, in the automotive industry, AI-powered pressure-controlled arms can adjust their movements to accommodate different types of materials, ensuring consistent quality.

Another innovation that has enhanced pressure-controlled arms is the development of advanced control systems. These systems allow for precise manipulation of the arm’s movements, enabling operators to program complex sequences of actions. This level of control is essential in applications where precision is critical, such as semiconductor manufacturing. Advanced control systems also facilitate remote operation, allowing operators to control the arm from a distance, which is particularly useful in hazardous environments.

Real-World Examples of Pressure-Controlled Arms in Action

The impact of pressure-controlled arms is evident in various real-world applications. In the electronics industry, these arms are used to assemble circuit boards with precision, ensuring that each component is placed accurately. This reduces the risk of defects and improves the overall reliability of electronic devices. In the aerospace sector, pressure-controlled arms are employed in the assembly of aircraft components, where precision is paramount for safety and performance.

In healthcare, robotic surgical systems equipped with pressure-controlled arms are transforming surgical procedures. They provide surgeons with enhanced dexterity and control, allowing for minimally invasive surgeries with reduced recovery times. Additionally, these arms are used in rehabilitation therapies, where they apply controlled pressure to assist patients in regaining mobility.

In the realm of construction, pressure-controlled arms are used to automate tasks that were traditionally labor-intensive. They apply coatings with precision, ensuring uniform coverage and reducing waste. Moreover, their ability to handle heavy materials with precision makes them invaluable for installing glass panels and other delicate elements in modern architectural designs.

Case Study: Improving Efficiency with Pressure-Controlled Arms

To illustrate the benefits of pressure-controlled arms, let’s consider a case study of a manufacturing company that implemented these tools to enhance its production line. Prior to the implementation, the company faced challenges in maintaining consistent quality in its products, leading to increased waste and customer complaints.

By integrating pressure-controlled arms into its production process, the company was able to achieve greater precision in its operations. The arms were used to apply adhesives and assemble components, ensuring that each product met the desired specifications. This resulted in a significant reduction in defects and an improvement in product quality.

The company also experienced a boost in efficiency, as the pressure-controlled arms allowed for faster production cycles. This enabled the company to meet increasing demand without compromising quality. Furthermore, the versatility of the arms allowed the company to adapt to changes in product design, providing a competitive edge in the market.

The Future of Pressure-Controlled Arms

As technology continues to evolve, the future of pressure-controlled arms looks promising. Ongoing research and development are focused on enhancing the capabilities of these tools, making them even more precise, efficient, and versatile. In this section, we will explore some of the potential advancements that could shape the future of pressure-controlled arms.

One area of focus is the integration of advanced materials in the construction of pressure-controlled arms. Lightweight and durable materials could improve the performance of these arms, allowing for faster movements and reduced energy consumption. Additionally, the use of smart materials that can change their properties in response to external stimuli could further enhance the adaptability of pressure-controlled arms.

Another promising development is the incorporation of virtual reality (VR) and augmented reality (AR) technologies into the operation of pressure-controlled arms. These technologies could provide operators with real-time visual feedback, improving their ability to control the arm with precision. VR and AR could also be used for training purposes, allowing operators to practice complex tasks in a simulated environment before performing them in real life.

The integration of the Internet of Things (IoT) is also expected to play a significant role in the future of pressure-controlled arms. By connecting these arms to a network of devices, operators can monitor their performance in real time and make adjustments as needed. This connectivity could lead to improved maintenance practices, reducing downtime and extending the lifespan of the arms.

Challenges and Opportunities in Advancing Pressure-Controlled Arms

While the future of pressure-controlled arms is promising, there are challenges that need to be addressed to fully realize their potential. One challenge is the high initial cost associated with these arms, which can be a barrier for small and medium-sized enterprises. However, as technology advances and production costs decrease, pressure-controlled arms are expected to become more accessible to a wider range of businesses.

Another challenge is the need for skilled operators who can effectively control pressure-controlled arms. Training programs and educational initiatives will be crucial in ensuring that operators are equipped with the necessary skills to maximize the benefits of these tools. This presents an opportunity for educational institutions and training providers to develop specialized programs that cater to the needs of industries that rely on pressure-controlled arms.

Video Insight: Enhancing Precision in Manufacturing

To gain a deeper understanding of how pressure-controlled arms are enhancing precision in manufacturing, watch this insightful video: Master Precision in Manufacturing with Robotic Arms 🎥. This video provides a detailed overview of the technology and its applications in various industries, offering valuable insights into the future of precision-controlled tools.

Conclusion

In conclusion, the integration of pressure-controlled arms into various industries marks a revolutionary step forward in achieving precision and efficiency. Throughout this article, we’ve explored the multifaceted benefits of these advanced tools, from their ability to enhance accuracy and control in delicate tasks to their role in optimizing productivity across diverse sectors such as manufacturing, healthcare, and robotics. By enabling more precise manipulation, these arms not only minimize human error but also contribute to higher quality outcomes, fostering innovation and excellence.

A key point we’ve examined is the versatility of pressure-controlled arms. Their adaptability to different environments and applications demonstrates their indispensable value in modern technological landscapes. Whether it’s in performing intricate surgical procedures or assembling complex components in manufacturing, these arms prove to be an essential asset, enabling professionals to achieve results that were once deemed unattainable.

Moreover, the economic implications are significant. By reducing waste and improving efficiency, businesses can not only cut costs but also enhance their competitive edge in the market. This economic advantage is coupled with the environmental benefits of reduced resource consumption, aligning with global sustainability goals. The deployment of such technology signifies a commitment to not only improving operational processes but also to contributing positively to broader societal and environmental objectives.

The importance of continuous innovation in pressure-controlled arm technology cannot be overstated. As we look to the future, the potential for advancements in this field promises even greater capabilities. The integration of AI and machine learning, for example, could further enhance the functionality and adaptability of these systems, allowing them to learn from previous tasks and improve their precision over time. Such developments would undoubtedly open new frontiers in what can be achieved, setting new standards for precision and efficiency.

Encouragingly, the collaborative nature of advancements in pressure-controlled arm technology invites input and innovation from diverse fields. Engineers, designers, medical professionals, and researchers all have a role to play in shaping the future of these tools. This interdisciplinary approach ensures that as we refine and expand the capabilities of pressure-controlled arms, they remain relevant and responsive to the ever-evolving needs of various industries.

The journey to mastering precision with pressure-controlled arms is one that holds promise for incredible achievements. It’s a journey fueled by curiosity, innovation, and a relentless pursuit of perfection. As we stand on the cusp of this technological frontier, the invitation is open to all who wish to contribute, share, and explore. Whether you’re a seasoned professional in the field or an enthusiastic newcomer, your insights and ideas are valuable.

Feel inspired to take what you’ve learned and apply it to your own projects, pushing the boundaries of what’s possible. Share this knowledge with others who might benefit from understanding the transformative potential of pressure-controlled arms. By fostering a community of informed and engaged individuals, we can collectively drive the innovation necessary to harness these tools to their fullest potential.

Let’s embrace this technological evolution with enthusiasm and responsibility. By doing so, we not only enhance our capabilities but also set a precedent for future generations, ensuring that precision, efficiency, and sustainability remain at the forefront of technological advancement. Your engagement, whether through comments, discussions, or applications of this knowledge, plays a vital role in this exciting journey. Together, let’s strive for excellence in every project, fueled by the ultimate tool for perfect results: pressure-controlled arms. 🤖✨

Toni Santos is a visual historian and creative artisan whose work channels the bold spirit of the steam-powered era—a time when imagination, mechanics, and ambition converged to reshape the modern world. Through richly detailed visual narratives and handcrafted design, Toni celebrates the legacy of steam innovation as both an artistic and technological revolution.

Driven by a passion for mechanical aesthetics, forgotten inventions, and industrial-age ingenuity, Toni reimagines the world of steam through illustrations, tactile artifacts, and storytelling that capture the poetry of pressure, motion, and invention. From piston-driven engines to brass-detailed diagrams, each piece reveals how steam wasn’t just power—it was promise.

With a background in visual design and historical research, Toni brings a craftsman’s eye and a dreamer’s heart to the stories of tinkerers, inventors, and visionaries who shaped the 19th century. His work doesn’t merely document machines—it honors the culture, courage, and creativity that drove a world to reimagine itself through gears, valves, and vapor.

As the creative voice behind Vizovex, Toni shares curated articles, reconstructed blueprints, and visual interpretations that bring this industrial past to life. His collections serve as a tribute to:

The elegance of steam-era design and innovation

The human stories behind great mechanical feats

The aesthetic beauty found in function and form

The echo of invention in today’s creative world

Whether you’re a history lover, a fan of steampunk, or an admirer of antique technology, Toni welcomes you into a world where art and machinery fuse, one cog, one drawing, one rediscovered marvel at a time.