In the ever-evolving world of maritime engineering, where every knot of speed and every drop of fuel can make a significant difference, optimizing the layout of an engine room has become a crucial aspect of ship design. The engine room, often referred to as the “heart” of a vessel, is where the magic happens, transforming fuel into the propulsion that powers ships across vast oceans. Yet, it’s a space that poses numerous challenges, demanding a blend of science, art, and a touch of engineering wizardry to get it just right. 🚢 In this comprehensive exploration, we delve deep into the intricacies of engine room layouts, shedding light on how strategic design can unlock unprecedented levels of efficiency and performance.

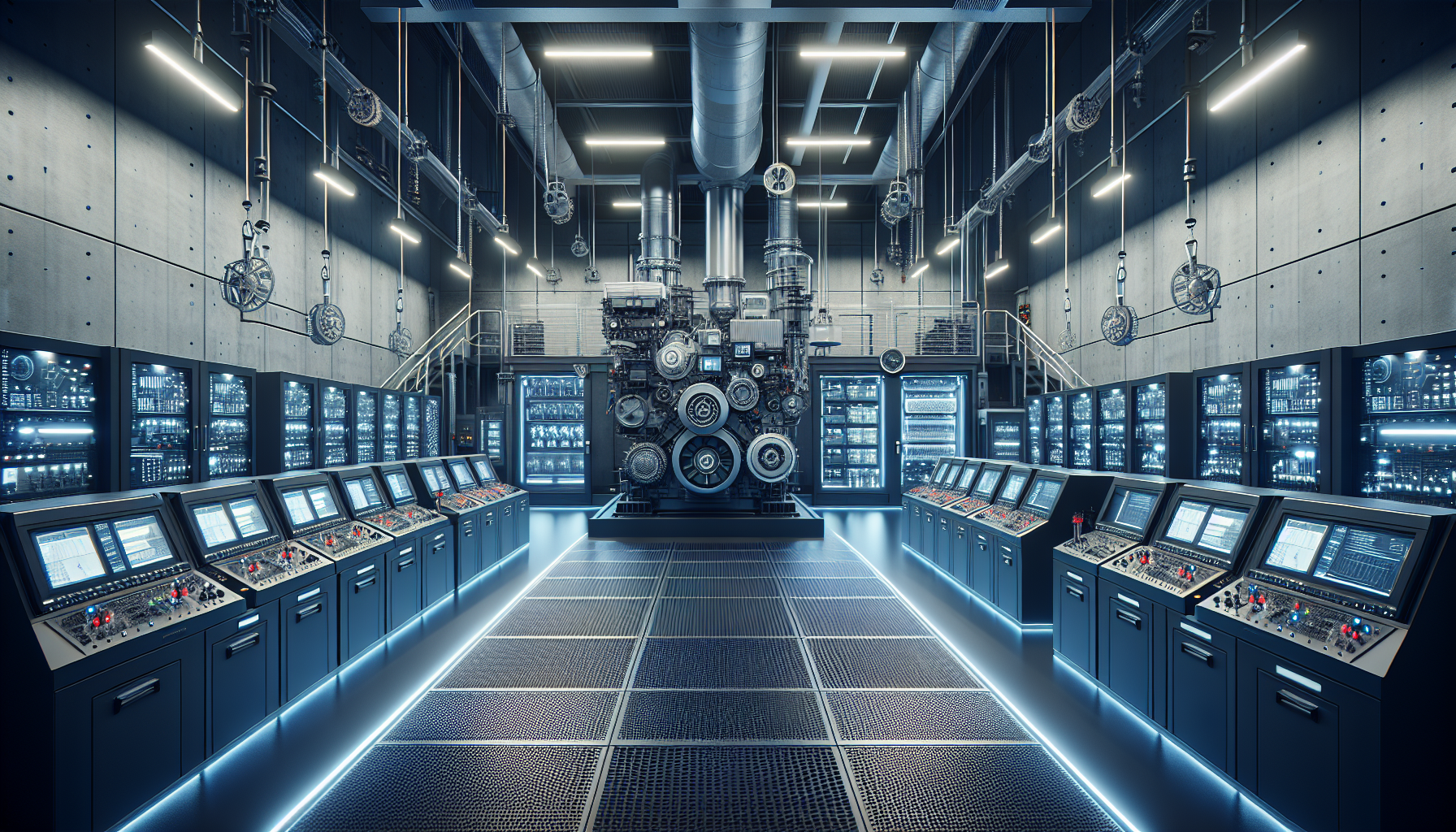

At the heart of our discussion is the quest for maximum performance, a goal shared by shipbuilders, operators, and engineers alike. But what does an optimal engine room layout truly entail? It’s about more than just fitting machinery into a confined space; it’s about creating a harmonious environment where each component operates at peak efficiency. This involves a careful balance of factors such as accessibility, safety, and thermal management. As we set sail on this enlightening journey, we will explore the latest innovations in engine room design, drawing on real-world examples and expert insights to guide our understanding.

One of the key topics we will explore is the importance of spatial arrangement and ergonomics in engine room design. How do these elements impact the day-to-day operations and maintenance of a vessel? The arrangement of machinery not only affects the ease of access for routine inspections and repairs but also influences the overall safety and efficiency of the engine room. From the placement of engines to the positioning of control panels, every detail matters. We will also delve into the role of advanced technologies, such as computer-aided design (CAD) and virtual reality (VR), in planning and visualizing these complex environments before a single piece of equipment is installed.

Additionally, we will examine the impact of regulatory standards and environmental considerations on engine room layouts. In an era where sustainability is at the forefront of global maritime policies, how can shipbuilders design engine rooms that not only comply with stringent regulations but also contribute to a vessel’s eco-efficiency? This includes exploring innovations in noise reduction, emission controls, and energy-saving technologies. 🌍 As we navigate through these topics, readers will gain valuable insights into the multifaceted nature of engine room design, ultimately equipping them with the knowledge to make informed decisions in their own maritime endeavors.

Understanding the Basics of Engine Room Design

When it comes to the design and layout of engine rooms, efficiency is key. Optimal engine room layouts not only ensure that machinery operates at peak performance but also facilitate easier maintenance and repairs. These considerations are crucial in sectors ranging from maritime shipping to power generation. But what exactly goes into designing an efficient engine room? The process involves careful planning, strategic placement of equipment, and a deep understanding of the operational requirements of the machinery involved.

An efficient engine room is like the heart of any mechanical operation. It must be designed to accommodate various components, including engines, compressors, pumps, and control systems, in a way that maximizes performance and minimizes downtime. The layout must also consider safety and accessibility, ensuring that technicians can easily navigate the space for routine checks and emergency interventions. This becomes increasingly complex in environments with space constraints, such as ships or offshore platforms.

Moreover, the choice of materials and construction techniques plays a significant role. Materials must withstand harsh conditions, including high temperatures, moisture, and corrosive elements. Advanced technologies like computer-aided design (CAD) software have revolutionized how engineers approach engine room layouts. By simulating different configurations, engineers can visualize potential issues and optimize the arrangement of components before the physical construction begins.

Key Elements of an Optimal Engine Room Layout

Creating an optimal engine room layout involves several critical elements. First, the placement of the main engine must be strategic to balance weight distribution and ensure stability, especially in maritime vessels. The engine should be easily accessible for maintenance and repairs. This is often achieved by placing it centrally and ensuring adequate space around it for maneuverability.

Next, the arrangement of auxiliary systems such as generators, cooling systems, and exhaust systems is essential. These systems must be positioned to facilitate the efficient flow of fluids and gases, minimizing energy loss. For example, cooling systems should be located to take advantage of natural ventilation and reduce the reliance on powered ventilation systems. In this context, redundancy and backup systems must also be considered to ensure continuous operation in case of equipment failure.

Additionally, safety is a non-negotiable aspect of engine room design. The layout must comply with safety regulations and standards, incorporating features like fire suppression systems, emergency exits, and clear labeling of all machinery. The use of non-slip flooring and adequate lighting further enhances safety, reducing the risk of accidents and injuries. For a detailed overview of safety considerations, check out the video “Safety Measures in Engine Room Design” on the Marine Engineering Channel.

Technological Advancements in Engine Room Design

The advent of technology has brought significant advancements in engine room design, transforming traditional layouts into more sophisticated and efficient systems. One of the most impactful technologies is the integration of smart systems and automation. These systems enable real-time monitoring of engine performance and environmental conditions, allowing for predictive maintenance and reducing downtime.

Smart sensors and IoT devices collect data continuously, feeding it into centralized systems where it is analyzed to predict potential failures and optimize performance. This approach not only extends the life of machinery but also ensures that the engine room operates at peak efficiency at all times. For those interested in the technical aspects of these innovations, the video “How IoT is Revolutionizing Engine Rooms” on the Tech Innovations Channel provides valuable insights.

Furthermore, virtual reality (VR) and augmented reality (AR) are being utilized in the design and training phases. Engineers can use VR to explore engine room layouts in a virtual environment, identifying potential issues and making necessary adjustments before implementation. AR, on the other hand, aids technicians by overlaying digital information on physical components, providing guidance during maintenance tasks. This technology not only enhances training effectiveness but also reduces the likelihood of human error.

Case Studies: Successful Engine Room Layouts

Examining successful case studies offers valuable lessons in engine room layout design. One notable example is the layout of modern LNG carriers, which have been optimized for both performance and environmental compliance. These ships feature innovative engine room designs that prioritize fuel efficiency and emission reduction, using dual-fuel engines that can operate on both LNG and diesel.

The layout of these engine rooms incorporates advanced insulation techniques to minimize heat loss and maximize energy efficiency. Additionally, the integration of waste heat recovery systems further enhances overall performance by converting exhaust heat into usable energy. This not only reduces fuel consumption but also decreases greenhouse gas emissions, aligning with international environmental standards.

Another impressive example is the design of engine rooms in modern cruise ships. These vessels require complex layouts to support numerous amenities while ensuring smooth operation. The engine rooms are strategically located to optimize space and reduce noise and vibration, enhancing passenger comfort. Advanced propulsion systems, such as azipods, are used to improve maneuverability and fuel efficiency. For a visual tour of these advanced engine rooms, watch the video “Inside a Cruise Ship Engine Room” on the Maritime Exploration Channel.

Comparative Analysis of Engine Room Layouts

To fully appreciate the impact of different engine room layouts, it’s useful to compare them across various industries. The table below highlights key differences between marine and industrial engine room designs, focusing on factors such as space utilization, safety features, and technological integration.

| Aspect | Marine Engine Rooms | Industrial Engine Rooms |

|---|---|---|

| Space Utilization | Compact, due to vessel size constraints | More spacious, allowing for larger equipment |

| Safety Features | Emphasis on fire suppression and watertight doors | Focus on ventilation and temperature control |

| Technological Integration | Advanced navigation and communication systems | Automation and IoT for process optimization |

By understanding these differences, engineers and designers can make informed decisions when planning new engine room layouts or upgrading existing ones. For a deeper dive into these differences, watch the video “Comparing Marine and Industrial Engine Room Designs” on the Engineering Insights Channel.

Conclusion

Creating an optimal engine room layout is an intricate yet vital aspect of marine engineering that can significantly enhance a vessel’s performance, safety, and longevity. Throughout this article, we have explored several key elements that contribute to unlocking efficiency within these critical spaces.

Firstly, we delved into the core principles of engine room design, emphasizing the importance of strategic space allocation. By prioritizing the placement of essential machinery and equipment, engineers can ensure that operations are not only streamlined but also safe and accessible for the crew. Proper spatial arrangement minimizes the risk of accidents and enhances the ability to conduct routine maintenance and emergency repairs.

Next, we discussed the integration of advanced technologies within engine room layouts. Modern ships benefit from innovations such as automated systems and digital monitoring tools that enhance operational efficiency. These technologies not only reduce human error but also facilitate real-time data analysis, enabling more informed decision-making. The impact of such technological advancements on fuel efficiency and environmental sustainability cannot be understated, as they play a critical role in reducing emissions and operational costs.

We also examined the importance of ergonomic design in engine rooms. By considering the human element, engineers can create work environments that reduce fatigue and improve productivity. Ergonomically designed spaces allow crew members to perform their duties more effectively, which in turn contributes to the overall efficiency of the vessel. Attention to details such as lighting, noise control, and vibration reduction can significantly impact the well-being and performance of the crew.

Furthermore, the article highlighted the significance of regular maintenance and updates to engine room layouts. As technology evolves and regulations change, it is crucial for ship operators to remain vigilant and proactive in implementing necessary upgrades. This ensures that vessels remain compliant with international standards and continue to operate at peak efficiency.

The financial implications of optimizing engine room layouts were also addressed. While initial investments may be substantial, the long-term savings in fuel consumption, maintenance costs, and extended machinery lifespan make it a worthwhile endeavor. Moreover, efficient engine room designs can increase a vessel’s resale value, offering financial benefits to ship owners.

Finally, we underscored the environmental impact of efficient engine room layouts. With the maritime industry under increasing pressure to reduce its carbon footprint, optimizing engine rooms is a significant step toward achieving sustainability goals. By minimizing fuel consumption and emissions, ship operators can contribute to global efforts to combat climate change.

In conclusion, the optimization of engine room layouts is a multifaceted approach that requires careful planning, technological integration, and a commitment to continuous improvement. The benefits of such optimization extend beyond performance and cost savings, encompassing safety, crew well-being, and environmental responsibility. As the maritime industry evolves, embracing these principles will be crucial in meeting the demands of the future.

We encourage readers to reflect on the insights shared in this article and consider how they can apply these principles to their own operations. Whether you are a ship owner, operator, or marine engineer, there is always room for improvement. By sharing this knowledge and engaging in discussions with peers, you can contribute to a more efficient and sustainable maritime industry. Feel free to comment below with your thoughts or share this article with colleagues who might find it valuable. Together, we can work toward unlocking the full potential of our vessels and charting a course toward a brighter future. 🌊⚓️

For further reading and research on this topic, you might find these resources helpful:

– Marine Engineering Best Practices

– Sustainable Shipping Initiatives

– Advancements in Maritime Technology

These links provide additional insights and are continuously updated to reflect the latest in maritime innovations and practices.

Toni Santos is a visual historian and creative artisan whose work channels the bold spirit of the steam-powered era—a time when imagination, mechanics, and ambition converged to reshape the modern world. Through richly detailed visual narratives and handcrafted design, Toni celebrates the legacy of steam innovation as both an artistic and technological revolution.

Driven by a passion for mechanical aesthetics, forgotten inventions, and industrial-age ingenuity, Toni reimagines the world of steam through illustrations, tactile artifacts, and storytelling that capture the poetry of pressure, motion, and invention. From piston-driven engines to brass-detailed diagrams, each piece reveals how steam wasn’t just power—it was promise.

With a background in visual design and historical research, Toni brings a craftsman’s eye and a dreamer’s heart to the stories of tinkerers, inventors, and visionaries who shaped the 19th century. His work doesn’t merely document machines—it honors the culture, courage, and creativity that drove a world to reimagine itself through gears, valves, and vapor.

As the creative voice behind Vizovex, Toni shares curated articles, reconstructed blueprints, and visual interpretations that bring this industrial past to life. His collections serve as a tribute to:

The elegance of steam-era design and innovation

The human stories behind great mechanical feats

The aesthetic beauty found in function and form

The echo of invention in today’s creative world

Whether you’re a history lover, a fan of steampunk, or an admirer of antique technology, Toni welcomes you into a world where art and machinery fuse, one cog, one drawing, one rediscovered marvel at a time.